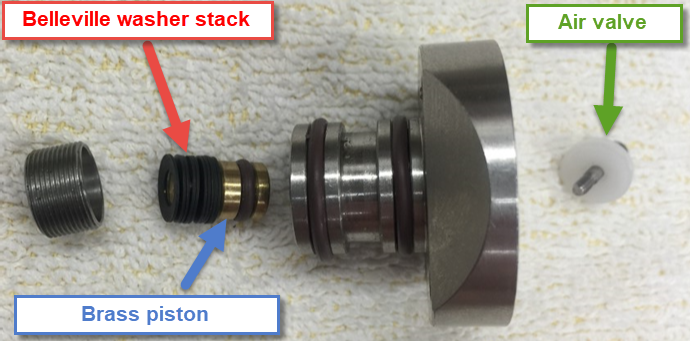

After a strip down and a significant number of tests, the deficiencies of the manufacturers regulator really became obvious. The

design is straightforward - using a brass piston opposed by a conventional Belleville washer stack (left side of picture) and which opens

or closes a valve made from a narrow tapered screw and a delrin washer (see the right side of picture). The piston is arranged so that it has atmospheric

pressure on one side of the crown and the regulated output (low) pressure on the other side of the crown. With the pistol empty, the belleville

washers relax, the piston rises in its bore and opens the connected air valve. After the reservoir is filled, high pressure air flows through the

open valve to fill the low pressure chamber. Given the piston has atmospheric pressure on side, then as the pressure builds in the low pressure

chamber, the piston experiences a pressure differential and so starts to compress, while being opposed by the domed belleville washers. When

enough pressure differential is present, the opposition from the belleville washers will be overcome and the piston will start to move down

in its bore flattening the belleville washers as it does and consequently closing the air valve. This movement occurs quite quickly, in the

order of hundreds of milliseconds.