Knowing that the MAF generates an output from 0 to 5v there are a couple of complications. The first is that unless the op-amp used is a very specialised type, running a rail of +5V means that when the op-amp is saturated, it will only ever reach

around 3.8v max. This is a normal op-amp characteristic and the only way to resolve it is either to use specialist op-amps or by simply using a supply rail higher than the 5v ceiling

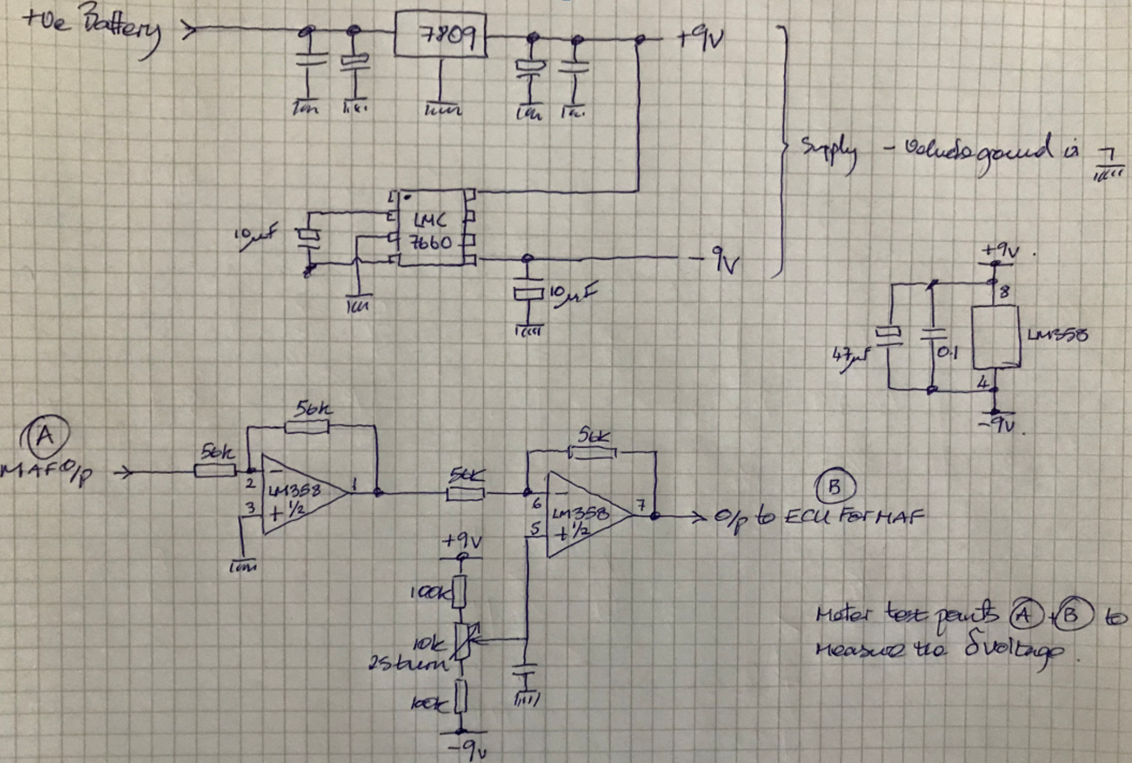

output we require. A supply of 9v works well in this regard and so I used a 7809 regulator. A second complication is the difficulty of building this circuit without using a split supply.

You’ll find that if you use a single supply of ground and +9v, once the input drops below 1v, the output will start separating from the input by increasingly large amounts and no amount

of adjusting will resolve the error (from 1v up, the circuit will operate reasonably well). A solution is to use a split supply which on first sight appears to be difficult but turns

out to be fairly easy as Brian explained. We use the +9v to drive an LMC7660 (switched capacitor voltage converter chip in 8 pin DIL) along with two 10uF capacitors to generate a low

current -9v output. Max current supplied by this device is only around 400uA but we only need around a third of that anyway - so perfect for the job.